User Ideas / Prospects

Now before you readers get this to some other way I must want to admit that. Science itself is more than just a philosophy. Even without direct engineering applications, scientific research advances our understanding of the universe, which is valuable in its own right. Pure science often drives innovation by pushing the boundaries of knowledge, which engineers later translate into practical applications.

The relationship between science and engineering is symbiotic rather than hierarchical. Engineers rely on scientific discoveries to innovate, and scientists often depend on engineering tools and technologies to conduct research. For example, advances in materials science or biomedical research often require sophisticated engineering tools and techniques.

And like wise Scientific research often relies on advanced tools and instruments, many of which are developed by engineers. For instance, modern physics would be unimaginable without the sophisticated particle accelerators designed by engineers, which allow scientists to probe the fundamental nature of matter.

Many scientific fields, such as astronomy or genomics, generate vast amounts of data. Engineers develop the technologies—like telescopes, sequencing machines, and data processing software—necessary for collecting, storing, and analyzing this data, enabling scientific discoveries.

Engineering innovations frequently lead to new experimental techniques. For example, advancements in materials science, a branch of engineering, have allowed scientists to explore the properties of new materials, leading to discoveries in nanotechnology and quantum computing.

Science provides the theoretical foundation and discoveries that engineers use to develop new technologies, while engineering provides the tools, techniques, and innovations that enable scientific research to advance. Both fields are crucial for progress, and each drives the other forward, leading to the continuous evolution of knowledge and technology.

So Science and Engineering both are interdependent wise versa.

but still ...

Engineers are responsible for applying scientific principles to solve real-world problems. Science provides the foundational knowledge, but engineering turns that knowledge into practical solutions, such as technology, infrastructure, and systems that benefit society. Without engineering, scientific discoveries might remain theoretical concepts, with limited impact on everyday life.

Engineers bridge the gap between scientific theory and practical implementation. For instance, while scientists may understand the principles of electromagnetism, it’s engineers who design and build electrical grids, smartphones, and computers. This practical application is what transforms scientific ideas into tangible realities.

Engineering is crucial for innovation and technological progress. Many of the advancements we associate with modern science—such as medical devices, renewable energy systems, and communication technologies—are the result of engineering efforts to harness scientific discoveries.

So "Without Engineers, Science Is Just a Philosophy" is a significant truth.

so I wrote this article to dedicate my gratitude to all of the Engineers who work hard on big important project with knowing that their name probably not going to shine only money as per market norm they are going to get but still they did work harder and smarter to make sure project don't get failed.

Long Live Engineering.

- Description: These kits typically include components like gears, pulleys, levers, and inclined planes. They are used to demonstrate fundamental mechanical principles such as force, torque, motion, and energy transfer.

- Common Uses: Educational demonstrations, basic experiments in statics and dynamics.

- Tools and Components:

- Gears (spur, bevel, worm)

- Pulleys and belts

- Levers and fulcrums

- Inclined planes

- Springs and weights

- Ropes and strings

- Force gauges

- Screw sets and nuts

- Description: Kits designed to study the motion of mechanisms, including linkages, cams, gears, and various types of motion converters (linear to rotational, etc.).

- Common Uses: Analysis of motion, design of mechanical linkages, study of velocity and acceleration in mechanical systems.

- Tools and Components:

- Linkages (four-bar, slider-crank)

- Cams and cam followers

- Gears and gear trains

- Shafts and axles

- Bearings

- Rotary encoders

- Stopwatches

- Protractors and rulers

- Description: These kits may include components like heat exchangers, thermocouples, and various setups to study conduction, convection, and radiation. They are used to demonstrate and experiment with the principles of thermodynamics and heat transfer.

- Common Uses: Demonstrating laws of thermodynamics, studying energy conversion processes, heat transfer experiments.

- Tools and Components:

- Heat exchangers

- Thermocouples and thermometers

- Insulating materials

- Heating elements (electric heaters, Bunsen burners)

- Calorimeters

- Pressure gauges

- Fans and blowers (for convection experiments)

- Radiation plates and sensors

- Description: Kits that include components like pumps, turbines, pipes, and flow meters. They are used to study fluid flow, pressure, and fluid-structure interactions.

- Common Uses: Demonstrating Bernoulli’s principle, studying laminar and turbulent flow, analyzing fluid systems.

- Tools and Components:

- Pumps (centrifugal, positive displacement)

- Flow meters (Venturi, orifice plate, rotameter)

- Piping and tubing

- Manometers and pressure gauges

- Valves (gate, ball, check)

- Turbines (small-scale)

- Nozzles and diffusers

- Fluid reservoirs

- Description: These kits typically include motors, sensors, controllers, and structural components to build and program robots. They may also come with software for simulation and control.

- Common Uses: Designing and programming robots, studying kinematics, automation, and control systems.

- Tools and Components:

- Servo motors and DC motors

- Microcontrollers (Arduino, Raspberry Pi)

- Sensors (ultrasonic, infrared, light)

- Wheels and tracks

- Structural components (beams, plates, fasteners)

- Breadboards and jumper wires

- Battery packs and power supplies

- Programming cables

- Description: Kits that provide components such as servos, controllers, sensors, and feedback devices to study control theory and implement control systems.

- Common Uses: PID controller experiments, stability analysis, automation tasks.

- Tools and Components:

- PID controllers

- Servos and actuators

- Sensors (temperature, pressure, position)

- Control loops (analog and digital)

- Microcontrollers or PLCs

- Oscilloscopes

- Signal generators

- Relay modules and switches

- Description: Kits that allow the study of vibrational characteristics of mechanical systems. They typically include components for generating and measuring vibrations, such as accelerometers, mass-spring systems, and damping materials.

- Common Uses: Studying natural frequencies, damping, and resonance in mechanical structures.

- Tools and Components:

- Accelerometers

- Vibration motors

- Springs and masses

- Damping materials (rubber pads, foam)

- Frequency counters

- Shakers (vibration generators)

- Signal analyzers

- Tunable mass dampers

- Description: These kits may include samples of different materials, testing equipment (like hardness testers), and tools for analyzing material properties such as tensile strength, elasticity, and fracture toughness.

- Common Uses: Material testing, failure analysis, studying the properties of metals, polymers, and composites.

- Tools and Components:

- Universal Testing Machine (UTM) components

- Hardness testers (Rockwell, Brinell)

- Sample materials (metals, polymers, composites)

- Microscopes (optical)

- Strain gauges

- Impact testers

- Metallurgical mounts

- Fracture analysis tools

- Description: Kits that include components like gears, shafts, bearings, and fasteners to design and test mechanical assemblies and systems. They may also include CAD files for 3D modeling.

- Common Uses: Prototyping mechanical systems, studying load distribution, stress analysis, and design optimization.

- Tools and Components:

- Gears (spur, helical, worm)

- Shafts and keys

- Bearings (ball, roller)

- Fasteners (bolts, nuts, washers)

- Sprockets and chains

- Couplings (rigid, flexible)

- Belts and pulleys

- Tolerance gauges and calipers

- Description: Kits focused on the principles of energy conversion, including components like solar panels, wind turbines, and small-scale engines. They are used to study and experiment with converting energy from one form to another.

- Common Uses: Experiments in renewable energy, studying thermodynamic cycles, efficiency analysis.

- Tools and Components:

- Small solar panels

- Wind turbine models

- Electric generators and motors

- Thermoelectric generators

- Batteries and energy storage devices

- Inverters and converters

- Energy meters and sensors

- Thermal engines (Stirling, steam)

- Description: Small-scale CNC kits that include a computer-controlled milling machine or lathe, along with the necessary software and tooling. These kits are used to introduce students and hobbyists to CNC machining.

- Common Uses: Prototyping, precision machining, learning CNC programming.

- Tools and Components:

- CNC milling machine or lathe

- Cutting tools (end mills, drill bits)

- Tool holders and collets

- Workholding devices (clamps, vises)

- Coolant system (basic)

- CAD/CAM software

- G-code generator

- Safety glasses and gloves

- Description: Kits that include a 3D printer and materials like PLA, ABS, or resin. These kits are used for prototyping and studying the principles of additive manufacturing.

- Common Uses: Rapid prototyping, custom part manufacturing, studying additive manufacturing processes.

- Tools and Components:

- 3D printer (FDM or resin)

- Filament or resin material

- Build plate and adhesives

- Nozzles and extruders

- CAD software

- Calibration tools (bed levelers, gauges)

- Scrapers and cutters (for part removal)

- UV light (for resin curing)

- Description: These kits include pumps, cylinders, valves, and actuators to demonstrate hydraulic and pneumatic systems. They are used to study the principles of fluid power and control.

- Common Uses: Building and controlling fluid power systems, studying hydraulic and pneumatic actuators.

- Tools and Components:

- Hydraulic pumps and cylinders

- Pneumatic actuators and valves

- Hoses and fittings

- Pressure gauges

- Flow control valves

- Reservoirs

- Compressors

- Control panels (manual or automated)

- Description: Kits designed to explore renewable energy technologies, often including small-scale solar panels, wind turbines, and associated measurement tools.

- Common Uses: Experiments in renewable energy generation, studying energy efficiency, and sustainability.

- Tools and Components:

- Small wind turbine blades and generator

- Solar panels

- Inverters and charge controllers

- Battery packs

- Energy meters

- Load resistors (for testing)

- Mounting hardware

- Simulation software (optional)

- Description: Kits that simulate automotive systems, including components like small engines, transmissions, braking systems, and suspension models.

- Common Uses: Studying vehicle dynamics, engine performance, and automotive systems design.

- Tools and Components:

- Small-scale engines (gasoline, electric)

- Transmission models

- Suspension systems (springs, dampers)

- Braking systems (disk, drum)

- Steering mechanisms Models

- Differential models

- Diagnostic tools (multi-meters, OBD scanners)

- Fuel and exhaust systems (carburetors, mufflers)

These kits are valuable resources for hands-on learning, experimentation, and the application of mechanical engineering principles in real-world scenarios.

common engineering jobs along with their primary subject matter expertise and essential skills that are considered foundational or "bread and butter" for each role:

All of listed expertise or knowledge are not written as each and every one of them are compulsory but at least 2-3 of them must have for advancement or progress in my opinion.

- Primary Subject Matter Expertise: Mechanics, Thermodynamics, Materials Science

- Bread and Butter Skills:

- CAD (Computer-Aided Design) software (e.g., SolidWorks, AutoCAD)

- Finite Element Analysis (FEA)

- Fluid dynamics and heat transfer

- Mechanical systems design and analysis

- Manufacturing processes and materials selection

- Primary Subject Matter Expertise: Circuit Design, Electromagnetism, Power Systems

- Bread and Butter Skills:

- Circuit analysis and design

- PCB (Printed Circuit Board) design and layout

- Control systems engineering

- Embedded systems and microcontroller programming

- Power generation and distribution

- Primary Subject Matter Expertise: Structural Analysis, Geotechnics, Fluid Mechanics

- Bread and Butter Skills:

- Structural design and analysis (e.g., using software like SAP2000, ETABS)

- Surveying and mapping techniques

- Soil mechanics and foundation design

- Hydraulics and water resources engineering

- Construction management and materials

- Primary Subject Matter Expertise: Algorithms, Data Structures, Software Development

- Bread and Butter Skills:

- Programming languages (e.g., Python, Java, C++)

- Software development methodologies (Agile, Scrum)

- Version control systems (e.g., Git)

- Data structures and algorithms

- Database management (SQL, NoSQL)

- Primary Subject Matter Expertise: Chemical Reactions, Process Design, Thermodynamics

- Bread and Butter Skills:

- Process simulation software (e.g., Aspen HYSYS, CHEMCAD)

- Chemical reaction engineering

- Heat and mass transfer

- Process control and instrumentation

- Safety and environmental regulations in chemical processes

- Primary Subject Matter Expertise: Aerodynamics, Propulsion, Structural Analysis

- Bread and Butter Skills:

- Aerodynamics and fluid dynamics

- Structural analysis for aerospace applications

- Propulsion systems (e.g., jet engines, rockets)

- Flight mechanics and control

- Materials science for aerospace (e.g., composites, alloys)

- Primary Subject Matter Expertise: Process Optimization, Operations Research, Human Factors

- Bread and Butter Skills:

- Process improvement techniques (Lean, Six Sigma)

- Operations research and optimization

- Supply chain management

- Human factors and ergonomics

- Statistical analysis and quality control

- Primary Subject Matter Expertise: Environmental Science, Water Resources, Waste Management

- Bread and Butter Skills:

- Environmental impact assessment

- Water and wastewater treatment processes

- Air quality management

- Waste management and remediation techniques

- Regulatory compliance and sustainability practices

- Primary Subject Matter Expertise: Biomedical Devices, Biomechanics, Systems Biology

- Bread and Butter Skills:

- Medical device design and testing

- Biomechanics and biological systems modeling

- Imaging and signal processing

- Biomaterials and tissue engineering

- Regulatory standards and medical ethics

- Primary Subject Matter Expertise: Materials Science, Metallurgy, Polymer Science

- Bread and Butter Skills:

- Material characterization techniques (e.g., X-ray diffraction, electron microscopy)

- Metallurgy and materials selection

- Polymer and composite materials design

- Failure analysis and materials testing

- Development of new materials and coatings

These core skills are essential for professionals in these roles and are often the foundation for further specialization within their respective fields.

there is huge gap between these two and thats actually leads to unemployment in engineering fields although there are lots of scope to work as an engineer but still lots of vacancy is not getting fulfilled and people get unemployed even though they got degree.

Academic Engineering and Industrial Engineering represent two distinct spheres within the broader field of engineering, each with its own focus, goals, and approaches. Here's a breakdown of the key differences between the two:

1. Purpose and FocusAcademic Engineering:

- Purpose: Focuses on the theoretical, scientific, and educational aspects of engineering. It aims to expand knowledge through research, teaching, and the development of new theories and methodologies.

- Focus: In-depth exploration of fundamental principles, mathematical modeling, simulations, and theoretical analysis. Academic engineers often work on advancing the frontiers of knowledge in their field.

Industrial Engineering:

- Purpose: Concerned with applying engineering principles to optimize processes, systems, and organizations within industries. The goal is to improve efficiency, productivity, and quality in real-world applications.

- Focus: Practical implementation of engineering knowledge in manufacturing, logistics, supply chain management, and operations. Industrial engineers work to solve practical problems and enhance industrial processes.

Academic Engineering:

- Research: Typically involves basic or fundamental research aimed at discovering new knowledge without immediate commercial application. Academic research often leads to publications in scientific journals and conferences.

- Development: May involve the development of new theories, algorithms, or techniques that contribute to the academic body of knowledge. Development is usually more conceptual and less concerned with immediate industrial application.

Industrial Engineering:

- Research: Focuses on applied research that directly addresses industry-specific challenges. Research is often driven by the need to solve specific problems or improve existing processes within a company or sector.

- Development: Involves the design, implementation, and optimization of processes, systems, or products. Development is closely tied to practical outcomes and often leads to new products, improved systems, or increased efficiency.

Academic Engineering:

- Application: Knowledge is applied primarily in an educational setting (teaching) or within research labs. The results may influence industrial practices but are often several steps removed from direct application.

- Outcome: Contributes to the theoretical foundation and future technologies. The impact on industry is typically long-term, as academic findings may take years to be applied.

Industrial Engineering:

- Application: Directly applies engineering principles to solve problems within industry. Industrial engineers work on projects that have immediate or short-term impacts on the company’s operations.

- Outcome: Results in tangible improvements in processes, cost savings, enhanced productivity, and quality within a relatively short timeframe.

Bridging the gap between academic engineering and industrial engineering can enhance innovation, improve practical outcomes, and ensure that theoretical advances translate effectively into real-world applications. Here are some strategies to help fulfill this gap:

1. Collaborative Research Initiatives- Industry-Academia Partnerships: Encourage collaborations between universities and industry to work on joint research projects. Companies can provide practical problems, while academic researchers can offer theoretical insights and advanced methodologies.

- Sponsored Research: Industries can sponsor research at universities focused on specific challenges they face. This ensures that academic research is aligned with industrial needs.

- Academic Internships: Encourage students and faculty to engage in internships or sabbaticals in industrial settings. This exposes academics to real-world challenges and gives them practical insights that can inform their research.

- Industry Fellowships: Create fellowships where industry professionals can spend time in academic institutions, sharing their practical experience and learning about the latest research developments.

- Problem-Based Learning: Integrate real-world industrial problems into the curriculum. Students can work on these as part of their coursework, bridging the gap between theoretical learning and practical application.

- Guest Lectures and Workshops: Invite industry professionals to give guest lectures or conduct workshops, bringing practical insights into the academic setting.

- University Research Centers: Establish research centers within universities that focus specifically on applied research. These centers can serve as hubs for industry-academic collaboration, focusing on solving practical engineering problems.

- Technology Transfer Offices: Universities can set up offices dedicated to technology transfer, helping to commercialize academic research and bring it to the market.

- Industry-Academic Roles: Encourage professionals to pursue dual careers in both academia and industry. For example, an academic might spend part of their time conducting research at a university and part of their time consulting for industry.

- Adjunct Professorships: Industry professionals can be appointed as adjunct professors, allowing them to contribute to academic teaching and research while remaining active in the industry.

- Joint Funding Programs: Governments and funding bodies can create programs that specifically support projects involving both academic institutions and industrial partners.

- Innovation Grants: Provide grants for collaborative projects that require academic research to be applied in an industrial context. This encourages both parties to work together toward a common goal.

- Conferences and Workshops: Organize events that bring together academics and industry professionals to share knowledge, discuss challenges, and explore collaborative opportunities.

- Online Platforms: Create online forums, databases, and platforms where industry and academia can share research findings, case studies, and best practices.

- Industry-Driven Curriculum: Involve industry representatives in curriculum development to ensure that academic programs are aligned with current industry needs and trends.

- Continuous Education Programs: Offer continuing education and professional development programs that allow industry professionals to stay updated with the latest academic research and engineering advancements.

- Post-Implementation Feedback: After implementing academic research in an industrial setting, gather feedback on its effectiveness. This feedback can inform future research and help academics understand the practical challenges of implementation.

- Industry Advisory Boards: Establish industry advisory boards for academic departments. These boards can provide insights into current industry needs and guide academic research priorities.

- Incubators and Accelerators: Universities can establish incubators and accelerators that support the commercialization of academic research. These can provide resources, mentorship, and connections to industry.

- Spin-Off Companies: Encourage the creation of spin-off companies from academic research, which can directly apply innovative ideas in a commercial context.

- Document and Share Successes: Publish case studies and applied research papers that detail successful industry-academic collaborations. Sharing these success stories can inspire more partnerships.

- Applied Engineering Journals: Promote the creation or use of academic journals that focus specifically on applied engineering, where research findings are directly related to industrial applications.

By implementing these strategies, the gap between academic and industrial engineering can be significantly reduced, leading to more effective innovation and practical outcomes that benefit both academia and industry.

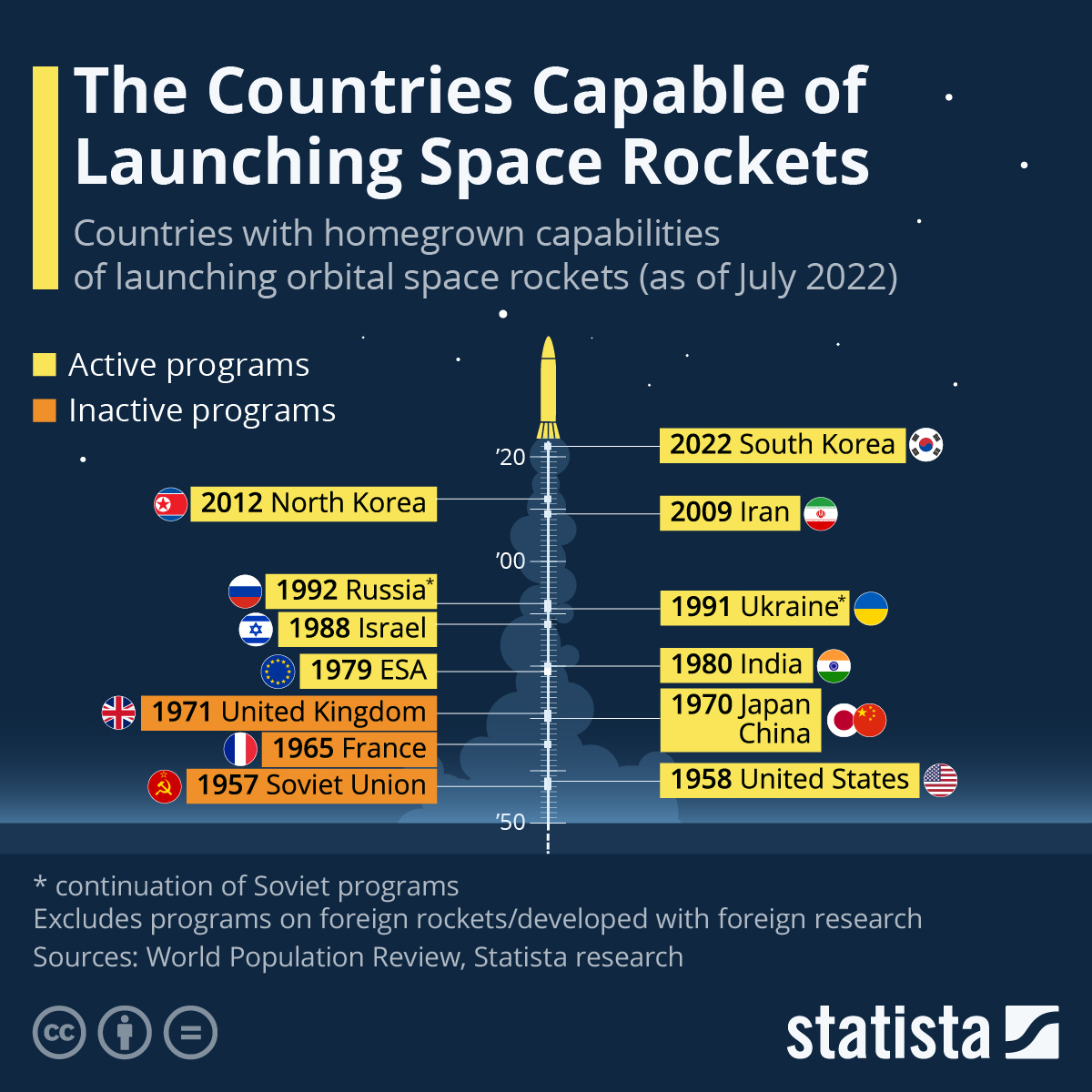

Several countries have developed their own rockets capable of launching payloads into space. These countries have invested in space programs that include the design, testing, and deployment of orbital rockets. Here is a list of countries that have successfully built and launched such rockets:

1. United States- Notable Rockets: Saturn V, Space Shuttle, Falcon 9, Delta IV, Atlas V, SLS (Space Launch System)

- Space Agency: NASA (National Aeronautics and Space Administration)

- Private Companies: SpaceX, Blue Origin, United Launch Alliance (ULA)

- Notable Rockets: R-7 (Soyuz), Proton, Zenit, Angara

- Space Agency: Roscosmos (Russian Federal Space Agency)

- Notable Rockets: Long March series (Chang Zheng), including Long March 3B, Long March 5

- Space Agency: CNSA (China National Space Administration)

- Notable Rockets: Ariane series (Ariane 5, Ariane 6)

- Space Agency: CNES (National Centre for Space Studies) and ESA (European Space Agency)

- Notable Rockets: H-IIA, H-IIB, Epsilon

- Space Agency: JAXA (Japan Aerospace Exploration Agency)

- Notable Rockets: PSLV (Polar Satellite Launch Vehicle), GSLV (Geosynchronous Satellite Launch Vehicle)

- Space Agency: ISRO (Indian Space Research Organisation)

- Notable Rockets: Shavit

- Space Agency: ISA (Israel Space Agency)

- Notable Rockets: Safir, Simorgh

- Space Agency: ISA (Iranian Space Agency)

- Notable Rockets: Unha series (derived from Taepodong-2)

- Space Agency: NADA (National Aerospace Development Administration)

- Notable Rockets: Naro-1, KSLV-II (Nuri)

- Space Agency: KARI (Korea Aerospace Research Institute)

- Notable Rockets: Black Arrow (historical; UK no longer has an active national rocket program but is involved in international collaborations)

- Space Agency: UKSA (UK Space Agency)

- Notable Rockets: VLS-1 (program was developed but not fully successful; Brazil is still active in space technology development)

- Space Agency: AEB (Brazilian Space Agency)

- Notable Rockets: Zenit, Tsyklon (inherited from Soviet-era technologies, Ukraine continues to develop space technologies)

- Space Agency: SSAU (State Space Agency of Ukraine)

In addition to the countries listed above, several other nations are actively developing or have developed rocket technology with varying degrees of success, including:

- Turkey: Developing the Gokturk series of rockets.

- United Arab Emirates: Partnering with other nations, with ambitions for indigenous rocket development.

- Australia: Developing the capability for launching small satellites.

These countries have made significant investments in their space programs, developing the necessary infrastructure, technology, and expertise to build and launch rockets capable of reaching space. The list is evolving as more nations seek to develop or expand their space capabilities, reflecting the growing global interest in space exploration and satellite deployment.

Drones are playing a pivotal role in the evolution of unmanned farms by providing a range of capabilities that enhance precision agriculture, improve farm management, and increase overall efficiency. Here’s how drones are contributing to the development of unmanned farms:

- Aerial Surveillance: Drones equipped with high-resolution cameras and multispectral sensors can capture detailed images of crops from above. These images help farmers monitor crop health, identify stressed areas, and detect issues like nutrient deficiencies, disease, or pest infestations.

- Early Detection: By regularly surveying fields, drones can spot early signs of problems, allowing farmers to take corrective action before issues become widespread. This leads to better crop management and higher yields.

- Targeted Spraying: Drones can be used for precision spraying of pesticides, herbicides, and fertilizers. They can apply these substances only where needed, reducing chemical use and minimizing environmental impact.

- Variable Rate Application: Drones can be programmed to adjust the application rate of inputs based on the specific needs of different areas within a field. This ensures that each part of the field receives the optimal amount of treatment, leading to more uniform crop growth and better resource utilization.

- Aerial Seeding: Some drones are capable of dropping seeds directly into the soil, enabling aerial seeding of crops, especially in difficult-to-reach or rugged terrain. This is particularly useful for reforestation efforts or planting cover crops.

- Precision Planting: Drones equipped with seed dispensers can plant seeds with high precision, ensuring even distribution and optimal spacing for crop growth.

- Soil Mapping: Drones can carry sensors that measure soil properties, such as moisture content, temperature, and nutrient levels. This data is used to create detailed soil maps, helping farmers understand soil variability and make informed decisions about irrigation, fertilization, and crop rotation.

- Topographic Mapping: By creating 3D maps of the terrain, drones help farmers plan more effective irrigation systems, manage water flow, and prevent soil erosion.

- Water Stress Detection: Drones equipped with thermal cameras can detect water stress in crops by identifying temperature variations. This helps farmers optimize irrigation schedules and ensure that crops receive adequate water.

- Monitoring Irrigation Systems: Drones can fly over irrigation systems to check for leaks, blockages, or inefficiencies, ensuring that water is being distributed evenly and effectively across the farm.

- Real-Time Data: Drones provide real-time data on various aspects of farm operations, enabling quick decision-making. The data collected can be analyzed to identify trends, predict yields, and optimize resource allocation.

- Integration with AI and IoT: Drones can be integrated into broader IoT systems on the farm, working in conjunction with ground-based sensors and automated machinery. AI algorithms can analyze drone data to provide actionable insights, making farm management more precise and efficient.

- Accurate Field Maps: Drones create accurate maps of fields, including boundaries, crop zones, and infrastructure. These maps are essential for planning and optimizing farm operations, especially in large or complex fields.

- Plant Counting and Density Measurement: Drones can count individual plants and measure plant density across fields, helping farmers monitor crop establishment and adjust planting strategies as needed.

- Crop Maturity Assessment: Drones can monitor crop maturity levels across large fields, helping farmers determine the optimal time for harvesting. This ensures that crops are harvested at peak quality and reduces the risk of losses.

- Guiding Autonomous Harvesters: Drones can provide aerial views and data that guide autonomous harvesting machines, improving the efficiency and accuracy of the harvest.

- Herd Surveillance: Drones can be used to monitor livestock, tracking their movements, health, and behavior. This is especially useful for managing large herds or in difficult terrain.

- Grazing Management: By monitoring pasture conditions and livestock distribution, drones help farmers manage grazing patterns, ensuring sustainable use of grazing lands.

- Climate and Weather Data: Drones can be equipped with sensors to monitor local climate and weather conditions, helping farmers adapt to changing conditions and plan their activities accordingly.

- Biodiversity and Ecosystem Health: Drones can be used to monitor the biodiversity and health of ecosystems on and around the farm, ensuring that farming practices are environmentally sustainable.

Drones are transforming unmanned farms by providing critical data, enabling precision agriculture, and automating various tasks. They allow for more efficient resource use, reduce labor costs, and increase crop yields, making farming more sustainable and profitable. As drone technology continues to evolve, it will likely become an even more integral part of modern agriculture, driving further innovation and efficiency in unmanned farms.

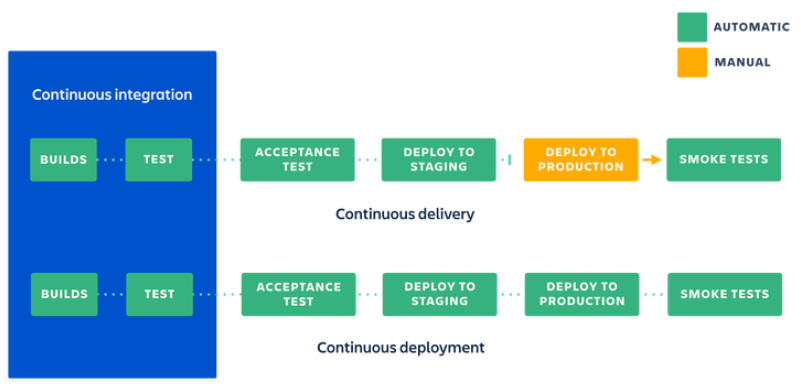

## Embracing CI/CD: Transforming Software Development

In today's fast-paced software development landscape, the demand for rapid delivery and high-quality applications has never been greater. Continuous Integration (CI) and Continuous Delivery/Deployment (CD) have emerged as essential practices that help teams meet these demands. This article explores the fundamentals of CI/CD, its benefits, and best practices for implementation.

### What is CI/CD?**

**Continuous Integration (CI)** is a development practice where code changes are automatically integrated into a shared repository several times a day. Each integration is verified by an automated build and testing process, allowing teams to detect errors quickly and improve software quality.

**Continuous Delivery (CD)** extends CI by ensuring that code changes are automatically prepared for a production release. This means that every change that passes automated tests can be deployed to production at any time, making the release process more predictable and less risky.

**Continuous Deployment** takes this a step further by automatically deploying every change that passes the tests to production, eliminating the need for manual intervention.

### Benefits of CI/CD

1. **Faster Time to Market**: By automating the integration and delivery processes, teams can release new features and updates more quickly, responding to customer needs and market changes in real time.

2. **Improved Code Quality**: Automated testing ensures that code changes are validated before they are merged, reducing the likelihood of bugs and improving overall software quality.

3. **Reduced Risk**: Smaller, incremental updates are easier to manage and roll back if issues arise. This minimizes the risk associated with large releases and helps maintain system stability.

4. **Enhanced Collaboration**: CI/CD fosters a culture of collaboration among development, operations, and quality assurance teams. Everyone works together towards a common goal of delivering high-quality software efficiently.

5. **Greater Customer Satisfaction**: With faster releases and higher quality, teams can better meet customer expectations, leading to increased satisfaction and loyalty.

### Key Components of CI/CD

1. **Version Control System (VCS)**: A VCS like Git is essential for managing code changes and facilitating collaboration among developers.

2. **Automated Build Tools**: Tools such as Jenkins, CircleCI, or GitHub Actions automate the process of compiling code and running tests, ensuring that changes are validated quickly.

3. **Automated Testing**: Implementing unit tests, integration tests, and end-to-end tests helps catch bugs early in the development process.

4. **Deployment Automation**: Tools like Kubernetes, Docker, and cloud services enable automated deployment to various environments, ensuring consistency and reliability.

5. **Monitoring and Feedback**: Continuous monitoring of applications in production allows teams to gather feedback and address issues proactively.

### Best Practices for Implementing CI/CD

1. **Start Small**: Begin with a single project or team to implement CI/CD practices. Gradually expand to other projects as the team gains experience.

2. **Automate Everything**: Aim to automate as many processes as possible, including builds, tests, and deployments. This reduces manual errors and speeds up the workflow.

3. **Maintain a Clean Codebase**: Encourage developers to write clean, maintainable code and adhere to coding standards. This makes it easier to integrate changes and reduces the likelihood of bugs.

4. **Use Feature Flags**: Implement feature flags to allow for gradual rollouts of new features. This enables teams to test new functionality in production without impacting all users.

5. **Continuously Monitor and Improve**: Regularly review CI/CD processes and gather feedback from the team. Look for areas to optimize and improve efficiency.

### Conclusion

CI/CD is not just a set of tools; it’s a cultural shift that transforms how software is developed and delivered. By embracing CI/CD practices, organizations can achieve faster delivery, improved quality, and greater collaboration among teams. As the software landscape continues to evolve, adopting CI/CD will be crucial for staying competitive and meeting the ever-changing demands of customers.

In the end, the journey to CI/CD is an ongoing process of learning and improvement, but the rewards are well worth the effort. Embrace the change, and watch your development process transform!

For seasoned software developers, the basics of SQL (Structured Query Language) might seem mundane. But beneath the surface of CRUD operations (Create, Read, Update, Delete) lies a powerful database language brimming with potential for complex data manipulation and analysis.

This blog post delves deeper into the advanced capabilities of SQL, showcasing its power in real-world scenarios.

Beyond the Basics:

We'll revisit the familiar example of a library management system. Imagine a scenario where you need to:

- Recommend books to users based on their borrowing history and genre preferences.

- Analyze trends in book borrowing patterns across different age groups.

- Identify overdue books and automate reminders for borrowers.

These tasks require going beyond simple CRUD operations.

Let's explore how SQL empowers us to handle such complexities..

1. Joins:

Joins are the cornerstone of retrieving data from multiple tables simultaneously. Imagine tables for Books, Authors, and Borrowers. By leveraging different types of joins (INNER JOIN, LEFT JOIN, etc.), we can fetch information like the author's name alongside the borrowed book title.

2. Aggregate Functions:

Functions like COUNT, SUM, AVG, etc., allow us to summarize data in meaningful ways. We can calculate the total number of books borrowed in a month or the average time it takes to return a specific genre of book.

3. Window Functions:

These functions operate on result sets within a single query. We can use them to rank books based on popularity (number of borrows) or identify the most frequent borrowers within a specific time period.

4. Views:

Views are virtual tables based on existing tables or queries. They offer a simplified data representation for specific user groups, enhancing security and maintainability. In our example, a separate view could display only borrowed books to library staff.

5. Stored Procedures:

Stored procedures are pre-compiled modules that encapsulate complex SQL statements. They promote code reuse, reduce redundancy, and enhance security by controlling access to underlying logic. We can create a stored procedure to automate sending overdue book reminders.

Code Snippet Breakdown (Refactored):

This section will highlight the refactored code, emphasizing how it demonstrates the concepts mentioned above. We can choose specific functionalities from the provided code, like searching for books by genre using joins or calculating overdue book statistics using aggregate functions.

Advanced Use Cases:

Lets see the.. real-world examples of how advanced SQL is used in various domains like:

- E-commerce: Analyzing customer purchase history and product recommendations.

- Financial Services: Detecting fraudulent transactions with complex queries.

- Data Science: Extracting and preparing data for further analysis in Python or R.

Hoping it will sharpen ur SQL Skills..if u have any Doudts regarding it.. feel free to ask on comment section

## Leveraging Emmet for Faster HTML Development

Tired of typing endless HTML tags? Meet Emmet, the productivity powerhouse that can revolutionize your web development workflow. This incredible tool transforms simple abbreviations into full-fledged HTML structures, saving you countless hours and reducing the risk of errors.

What is Emmet?

Emmet is a powerful code expansion tool that drastically speeds up HTML, CSS, and even JavaScript writing. It's like having a supercharged autocomplete feature on steroids. With Emmet, you can write less and achieve more, focusing on the logic and creativity of your project rather than the mundane task of typing out HTML elements.

### How Does Emmet Work?

Emmet operates on a simple yet effective principle: you provide a concise abbreviation, and Emmet expands it into the desired HTML structure. Here's a basic example:

Abbreviation: `div#container>h1+p#intro`Expanded HTML:

HTML

```

<div id="container">

<h1></h1>

<p id="intro"></p>

</div>

```

As you can see, Emmet not only creates the basic structure but also adds IDs and classes as specified in the abbreviation.

### Key Features and Benefits

- Rapid HTML Creation: Generate complex HTML structures with just a few keystrokes.

- Improved Efficiency: Save time and reduce repetitive tasks.

- Enhanced Code Readability: Create well-structured and organized HTML code.

- Reduced Errors: Minimize typos and syntax mistakes.

- Cross-Platform Compatibility: Works with most popular code editors and IDEs.

### Emmet Syntax Basics

To fully harness the power of Emmet, understanding its syntax is essential. Here are some fundamental elements:

- Element: Use element names like `div`, `span`, `p`, etc.

- ID: Precede an element with a `#` to assign an ID.

- Class: Precede an element with a `.` to assign a class.

- Child: Use `>` to create child elements.

- Sibling: Use `+` to create sibling elements.

- Multiplication: Use `*` to repeat elements.

- Text: Wrap text in quotes (single or double).

### Practical Examples

Let's explore some practical examples to illustrate Emmet's capabilities:

Creating a basic HTML structure:

```

html:5>head>title>My Page+body>div#container>h1#title>Hello, World!+p#intro>This is an introduction.

```

### Integrating Emmet into Your Workflow

To start using Emmet, you'll need a code editor or IDE that supports it. Popular options include Visual Studio Code, Sublime Text, Atom, WebStorm, and Brackets. Once you have a compatible editor, install the Emmet plugin or extension.

_fast forward.._

Emmet is an indispensable tool for any web developer looking to boost productivity and streamline the HTML creation process. By mastering its syntax and leveraging its features, you can significantly enhance your development workflow and create cleaner, more efficient code. Give Emmet a try and experience the difference it can make in your projects.

Have you tried Emmet yet? Share your experiences and tips in the comments below!

### How to Start Building a Project in C#

When embarking on a project in any programming language, the first questions that often come to mind are, “How do I start?” and “What initial steps are necessary?” This guide will help you start a project in C# efficiently.

**Setting Up Your Development Environment**

Before diving into coding, setting up your development environment is crucial. Here’s how to get started:

**Installing Visual Studio**

Visual Studio is the most comprehensive Integrated Development Environment (IDE) for C# development. Here’s how to install it:

1. **Download Visual Studio**

- Visit the [Visual Studio download page](https://visualstudio.microsoft.com/downloads/).

- Choose the version that suits your needs (Community, Professional, or Enterprise).

2. **Install Visual Studio**

- Run the installer.

- Select the necessary workloads for C# development:

- ASP.NET and web development for web applications.

- .NET Core cross-platform development for cross-platform applications.

- Desktop development with .NET for Windows desktop applications.

- Click **Install** and wait for the installation to complete.

**Installing Visual Studio Code**

If you prefer a lightweight editor, Visual Studio Code is an excellent choice. Here’s how to set it up:

1. **Download Visual Studio Code**

- Visit the [Visual Studio Code download page](https://code.visualstudio.com/Download).

- Download the installer for your operating system.

2. **Install Visual Studio Code**

- Run the installer and follow the instructions.

- Install the C# extension by OmniSharp from the Extensions marketplace.

**Creating a New Project**

Once your development environment is ready, you can create a new C# project.

**Using Visual Studio**

1. **Open Visual Studio**

- Click on **Create a new project**.

2. **Choose a Project Template**

- **Console App**: Ideal for simple command-line applications.

- **ASP.NET Core Web App (MVC)**: Suitable for building web applications following the Model-View-Controller pattern.

- **Blazor App**: For building interactive web UIs using C# instead of JavaScript.

- **ASP.NET Core Web API**: For creating RESTful APIs.

3. **Configure Your Project**

- Enter a project name and location.

- Select the framework version (usually the latest stable version).

- Click **Create**.

**Using Visual Studio Code**

1. **Open Visual Studio Code**

- Open the terminal (Ctrl + `) or navigate to View > Terminal.

2. **Install .NET SDK**

- If not already installed, download and install the .NET SDK from the [.NET download page](https://dotnet.microsoft.com/download).

3. **Create a New Project**

- Navigate to your desired project directory in the terminal.

- Use the `dotnet new` command to create a project:

- For a console app: `dotnet new console`

- For a web app: `dotnet new mvc`

- For a Blazor app: `dotnet new blazorserver` or `dotnet new blazorwasm`

- For a Web API: `dotnet new webapi`

4. **Open the Project**

- Use the `code .` command to open the current directory in Visual Studio Code.

**Running and Debugging Your Project**

**Running Your Project**

1. **Using Visual Studio**

- Click on the **Start** button or press F5 to run your project.

2. **Using Visual Studio Code**

- Open the terminal.

- Navigate to your project directory.

- Use the `dotnet run` command to run your project.

**Debugging Your Project**

1. **Using Visual Studio**

- Set breakpoints by clicking on the margin next to the line number.

- Click the **Start** button or press F5 to start debugging.

2. **Using Visual Studio Code**

- Set breakpoints by clicking on the margin next to the line number.

- Open the Run and Debug view (Ctrl+Shift+D).

- Click on **Run and Debug** or press F5.

**Conclusion**

Starting a C# project involves setting up your development environment, creating a new project, and understanding how to run and debug it. Whether you choose Visual Studio for a comprehensive IDE experience or Visual Studio Code for a lightweight editor, both provide the tools you need to build robust C# applications. By following these steps, you’ll be well on your way to developing your next C# project. Happy coding!

.png)